June 2019 Issue

Research Highlights

Technology for processing wood powder with natural additives

Biomass materials such as wood are environmentally-friendly alternatives to fossil resources. As an example, wood is typically non-toxic and carbon neutral. Furthermore, wood can be produced in a sustainable manner by appropriate planting and trimming of trees. Therefore, the use of wood resources as industrial materials is an important aspect for realizing a sustainable society.

Incorporating wood into industrial applications requires effective processing methods. Wood products are generally shaped by cutting processes because the deformability of wood is inferior to that of metals and plastics. Therefore, much of the original material is turned into waste chips or powder during the cutting process.

Shohei Kajikawa and colleagues at The University of Electro-Communications and Kyoto University developed injection molding of wood powder with sucrose, which is a natural binder, for fabricating products based on natural resources effectively.

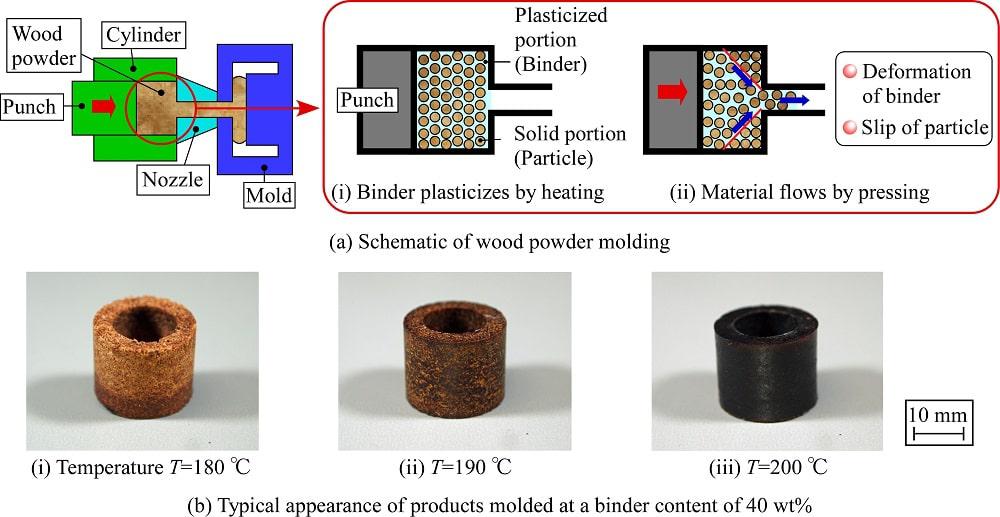

In the molding process, the binder plasticizes upon heating and the material, which is composed of the wood particles and the binder, flows due to the deformation of the binder and the slip of the particles. The binder solidifies between the particles upon cooling, and then the material is self-bonded. Fluidity of the material is important for improving moldabiliy, and changes drastically with molding conditions, such as temperature and binder content. Therefore, effects of added sucrose on the moldability of the wood powder were investigated, the molding conditions were optimized by thermal analysis, capillary flow test and injection molding.

As a result, the wood powder with the sucrose flowed at temperatures above 180 ºC, although flow was restricted above 220 ºC due to the effect of gases evolved from the sucrose. The minimum sucrose content required for flow was 30 wt% within the temperature range of 180 to 200 ºC. The material was filled in the mold under optimized conditions, and the product with good surface texture was molded at a sucrose content of 30 wt% and 200 ºC.

This proposed method allows the fabrication of products from naturally occurring materials with minimal environmental impact.

References

- Shohei Kajikawa, Masaya Horikoshi, Soichi Tanaka, Kenji Umemura and Kozo Kanayama.

- Title of original paper: Molding of wood powder with a natural binder.

- Journal, volume, pages and year: Procedia Engineering 207, 113-118 (2017).

- Digital Object Identifier (DOI): 10.1016/j.proeng.2017.10.747

- Department of Mechanical and Intelligent Systems Engineering, The University of Electro-Communications.

- Kuboki & Kajikawa Lab. website: http://www.mt.mce.uec.ac.jp/