March 2016 Issue

Research Highlights

Metal mesh filters: Calculating pressure drop

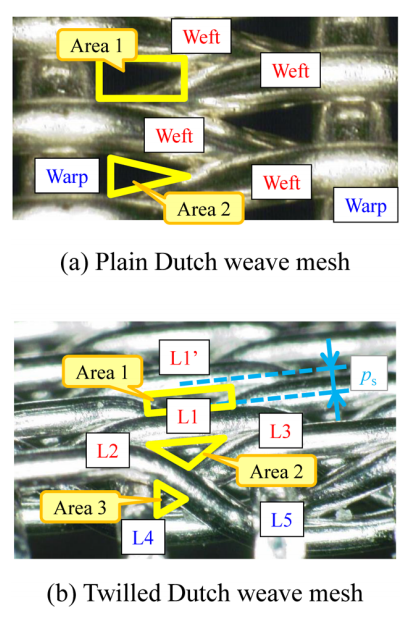

Metal woven meshes are used extensively as filters in multiple industrial settings, including the petrochemical and pharmaceutical industries. The meshes are carefully designed to allow only particles of a certain size to pass through apertures between the warp and weft. Two types of mesh - the plain Dutch weave and twilled Dutch weave - are particularly desirable because they have high mechanical strength, tiny apertures, and high pressure / heat resistance. However, because of the complexity of the flow paths that fluids take through these meshes, overall flow pressure drops as fluid is filtered.

Predicting this pressure drop is important for industry, because of the need to estimate operating power, output and filter lifespans. Now, Yohei Inoue at the University of Electro-Communications, Tokyo, Japan, together with scientists across Japan, have used computational fluid dynamics to model how liquids pass through plain Dutch weave and twilled Dutch weave meshes1. Their insights allowed them to derive an equation to predict pressure drop across the mesh structures.

The team first developed a computational model of the two mesh structures in three dimensions, together with accurate representation of the resulting aperture sizes in each mesh type. They were then able to clarify the flow patterns through the meshes on a microscopic scale, and visualize patterns of resulting drag forces which influence flow pressure. The model and subsequent numerical simulations allowed Inoue and his team to derive their pressure drop equations.

The researchers hope their equations will enable the design of a sophisticated Dutch weave filtration process in future.

Reference

- Yoshida, Y., Inoue, Y., Shimosaka, A., Shirawaka, Y., & Hidaka, J. Effect of aperture structure of Dutch weave mesh on flow resistivity. Journal of Chemical Engineering of Japan 48 (9) 730-741 (2015) doi: 10.1252/jcej.14we168